Copper-tin alloys are also known as bronze.Īn alloy containing zinc and copper, which has poor weldability and tends to give off offensive fumes. Tin adds hardness and strength to copper. Cold working adds strength and hardness.Ī metal’s ability to resist forces that attempt to squeeze or crush it.Ī reddish metal that is very ductile, thermally and electrically conductive, and resistant to corrosion.Īn allow containing lead and copper, which has the poorest weldability because the toxic lead often contaminates the weld.Īn alloy containing tin and copper, which is the most weldable of the copper alloys. The shaping of metal at temperatures substantially below the point of recrystallization. Cast nickel alloys are often difficult to weld because of their high silicon content. Extremely high welding temperatures can cause burn through.Īn alloy containing nickel that has been poured as a liquid into a mold and cooled into a solid shape. Bronze is the most weldable of the copper alloys.Įxcessive melt through or a hole in the base metal. Brass has poor weldability.Īn alloy of zinc and copper.

The boiling point of zinc is below the melting temperature of most steels.Īn alloy of zinc and copper. The temperature at which liquid changes to a vapor. One of the two or more metals to be welded together to form a joint. Austenitic stainless steel is the most corrosion resistant stainless steel. Stainless steel with very high strength, as well as excellent ductility and toughness. Argon is commonly used as a shielding gas. This molten mass then cools and solidifies into one solid piece.Ī colorless, odorless type of inert gas. The metal melts, while the edges are still molten, additional melted metal is added. To join two pieces of metal into one solid piece the heat of an electric arc is concentrated on the edges of two pieces of metal to be joined.

Annealing is often used when welding nonferrous metals.Ī fusion welding process that uses electricity to generate the heat needed to melt the base metals.

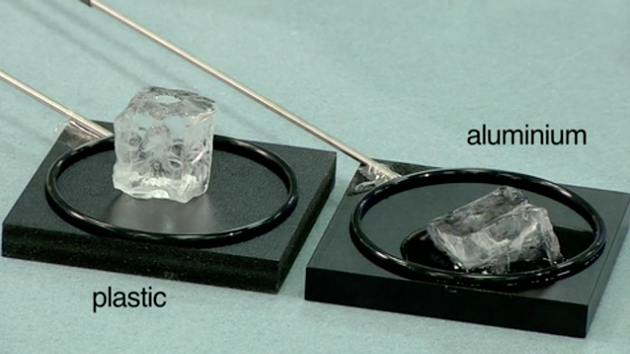

The steady heating of a metal at a certain temperature followed by a gradual cooling process. Aluminum oxides should be removed before welding. One of these materials must be a metal.Ī silver-white metal that is soft, light and conductive.Ī chemical compound of aluminum and oxygen, which forms a thin layer on the surface of aluminum when exposed to air. A metal consisting of a mixture of two or more materials.

0 kommentar(er)

0 kommentar(er)